EKME’s Engineering capabilities cover the entire scope of the company’s field and shop fabrication operations, from Pressure Equipment to Modular Units to Tanks & Piping. Our ability to provide these services in-house allow us to optimize our design work, execute faster and offer advance control over project execution parameters.

Engineering covers the following sectors:

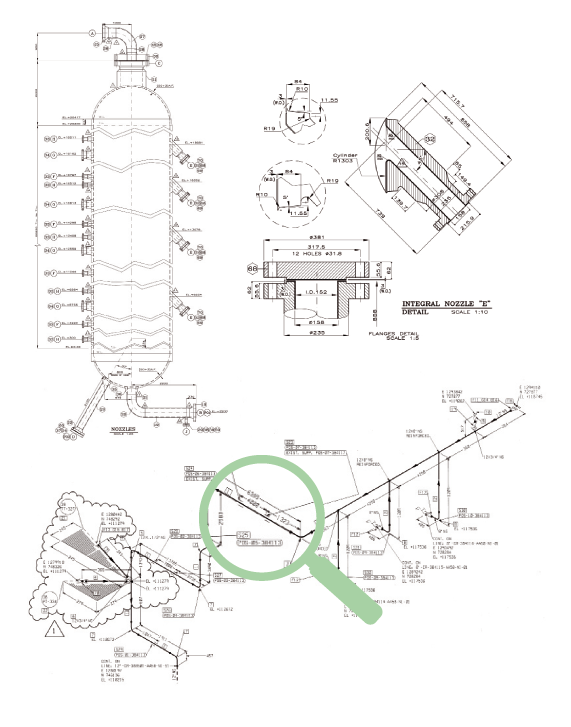

- Pressure Vessel mechanical detailed engineering and strength calculations

- Heat Exchangers thermal and mechanical detailed engineering

- Storage Tanks mechanical calculations

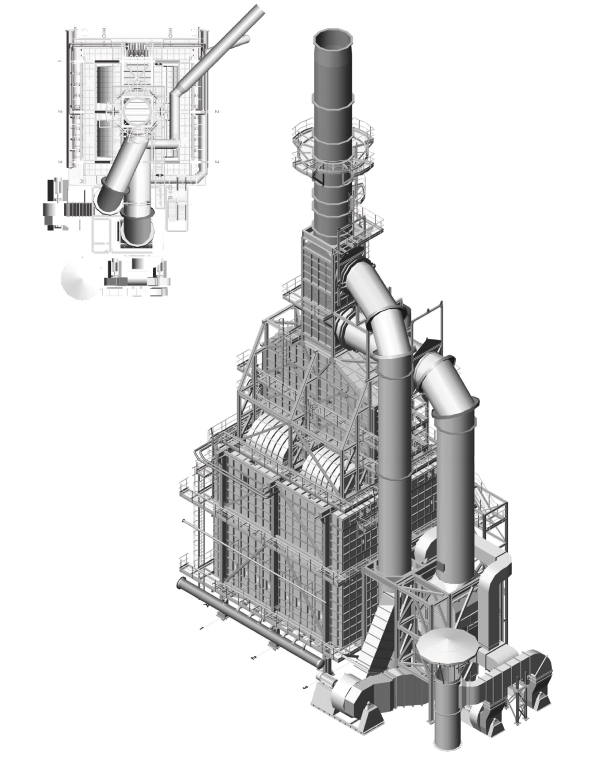

- Structural Steel detailed engineering

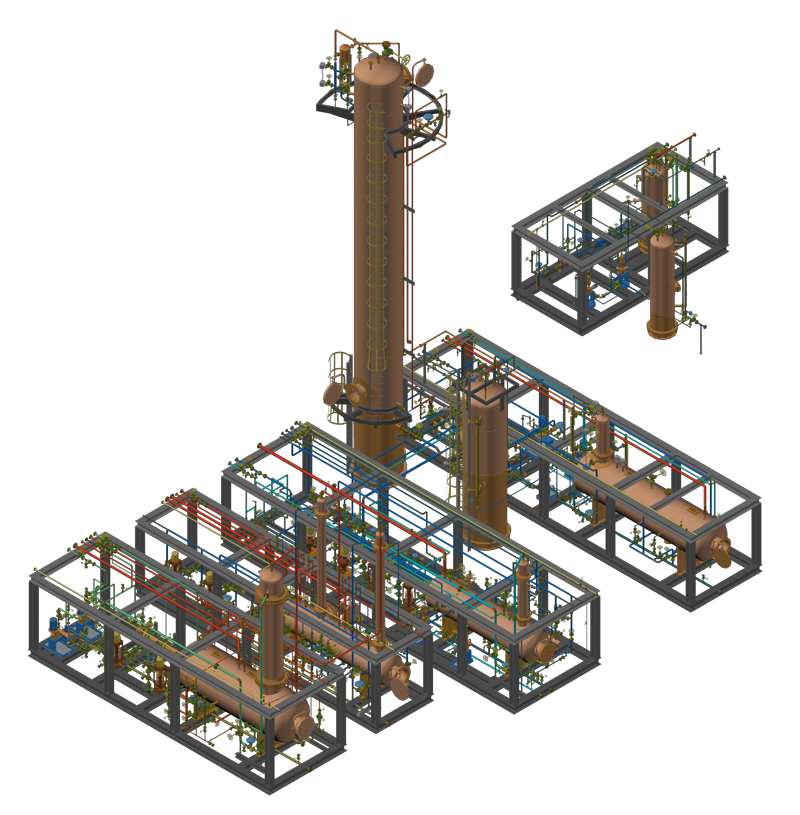

- 3-D Modelling of Skid & Modular Units

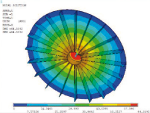

- Finite Element Analysis

- Piping detailed engineering & spooling

- E&I Detailed engineering

- Lifting studies

- Civil Construction detailed engineering

EKME designs and fabricates its equipment in accordance to the following codes:

- ASME VIII Div. 1, Div. 2

- PED 97/23/EC

- AD Merkblätter

- TEMA

- BS 5500

- API

- CODAP

- ISPESL

- GOST

Client’s special specifications can also be adopted

The detailed engineering of the process equipment is carried out by EKME using the Compress software by Codeware or PV Elite by COADE for ASME vessels. 3D visualization and isometric drawings of the units under construction, enable the efficient organization of the production procedure from the prefabrication to the final erection / assembly.

Software Packages

| Available calculation systems: | COMPRESS (CODEWARE) PV ELITE (COADE) TANK (COADE) |

|---|---|

|

Available CAD systems

Company ERP software |

AUTOCAD Entersoft Business Suite |

| Project Schedule software: | PRIMAVERA P3 MS PROJECT |

Other software packages:

> Storage Tanks Design: TANK by COADE

> Steel Structure Design: STRUCAD

> Piping / Spooling:

- PIPEWORX by COADE for piping works

- in-house developed software for engineering calculations to BS 5500

- SMART SPOOLGEN 2008.1 by INTERGRAPH for piping spooling

> 3D-Modelling of skid mounted units is performed using the Inventor software

| PROJECT | |

|---|---|

| Modular system to treat cocker stream and Spent Caustic Neutralization Stream | |

| LOCATION | CLIENT |

| Hellenic Petroleum s.a., Helefsis Refinery | MERICHEM Company |

Isometric for construction

| PROJECT | |

|---|---|

| Construction of one new double shell and convection Crude Oil Heater 3H01AB and the revamping of one existing Hot Oil Heater H101 |

|

| LOCATION | CLIENT / END USER |

| Elefsis Refinery | Hellenic Petroleum s.a. |

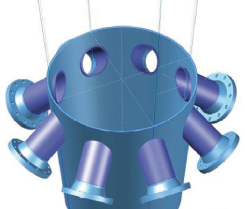

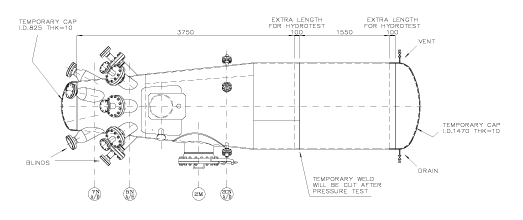

Feed Nozzle Cone detail

| PROJECT | Feed nozzle cone |

|---|---|

| LOCATION | Aspropyrgos Refineries |

| CLIENT / END USER | HELLENIC PETROLEUM s.a. |

| TOTAL LENGTH | 3.850mm |

| I.D. | 1470 x 825mm |

| Weight | 5.500 kgs |

| Shell material | A516 Gr 70 thickness 13mm |

| Third Party Inspection | Moody Tottrup Hellas S.A |

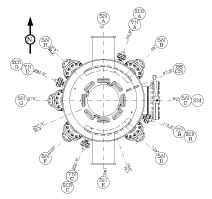

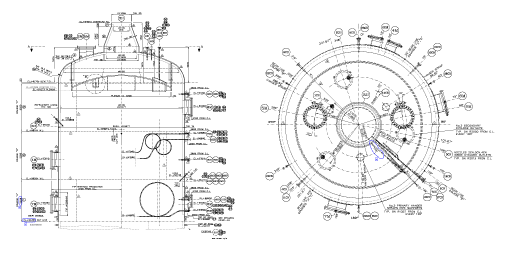

Design detail of New Feed Injector Cone & Straight Spool for Existing Feed Riser Line

Finite element Analysis of top part reactor included

1. 2.

2. 3.

3.

1. Thermal FEA, 2. Trunnion of the new FCC Top Part, 3. FEA of Bottom Flat Head with Radial Reinforcement Ribs

| Project | Top Part of 4101X FCC Reactor |

|---|---|

| Unit | Fluid Cracking |

| Location | Elefsis Refinery |

| Client user | Hellenic Petroleum s.a. |