EKME’s commitment to quality, in all aspects of its operations, has always been one of the company’s trademarks and the main reason behind its sustained success and growth through the years.

Certifications according to ISO standards (9001/3834-2/1090-2) and ASME U, U2, S stamps, National Board NB, R Stamps as well as TR-CU-032 Certifications cover all operations.

Responsibility for the implementation of the Quality Policy falls on all departments within the company’s organization. This approach promotes the concept of a company-wide quality culture, essential for achieving final product quality.

Project quality is controlled through a mandatory, job-specific Quality Assurance / Quality Control Plan issued by EKME’s Quality Management Department and applied to all stages of production process. Through extensive knowledge of the codes’ requirements and attention to client’s demands, all quality control activities and acceptance criteria are clearly defined and scheduled.

Depending on the needs, the QA/QC activities could also be subcontracted. Other sub-contracted activities are:

- Radiographic Testing (x-ray, γ-ray)

- UT T.O.F.D.

- Laboratory Chemical Analysis

- Disbonding Tests of Bimetallic Materials and Welds (ASTM G146)

- Laboratory Destructive Tests (incl. Elevated Temperature Tensile Test)

- Pitting / Crevice tests (ASTM G48)

- Ferrite count by metallographic examination (ASTM E562)

EKME’s Quality Management Department overviews these activities, directs and controls our specialized subcontractor in the execution of the quality tests and then interprets the results. Final acceptance of the test reports falls under EKME’s responsibility.

Furthermore, the client has always the option of appointing a third party inspection agency to ensure compliance to the applicable codes and standards. EKME can easily accommodate such an arrangement by incorporating third party inspection (T.P.I.) in the QA/QC plan and providing full access to inspectors during production and testing.

EKME can perform the following QA/QC activities in-shop:

- PWHT in furnace

- Local PWHT

- VT (with or without aids)

- UT Conventional

- UT thickness

- UT Phased Array

- PT conventional

- PT fluorescent

- MT conventional

- MT fluorescent

- Painting DFT measurements

- PMI (Including Light Elements and precious metals)

- Ferrite checking

- Hardness test (both UCI and Rebound)

- Radiographic Interpretation

- Ferrycyanide Test

- Ferroxyl Test

- Pickling / Passivation

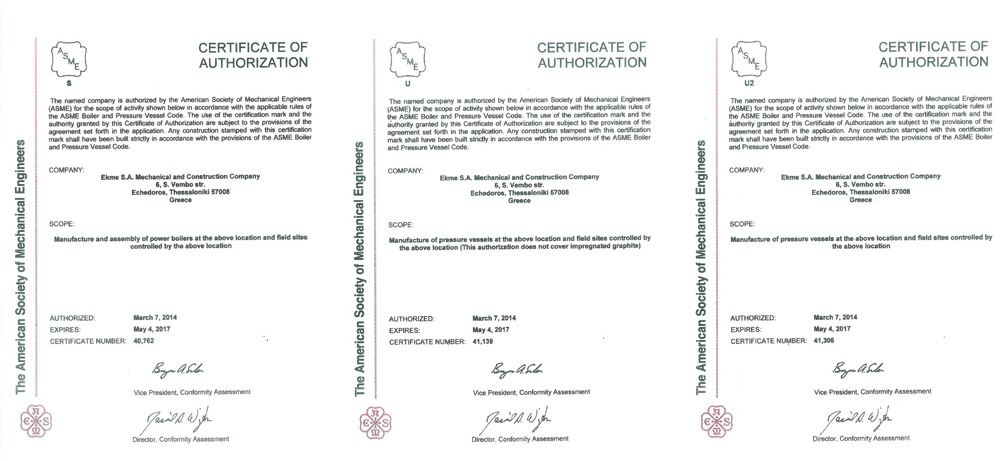

ASME Certification

EKME is certified by ASME’s Joint Review Committee and holds the U, U2 and S Certification Marks

ISO 9001:2015

EN ISO 3834-2 (EN 729-2)

Quality Requirements for Fusion Welding of Metallic Materials- Comprehensive quality requirements

EN ISO 1090-2

Design, Construction and Erection of Steel Structures Class EXC2

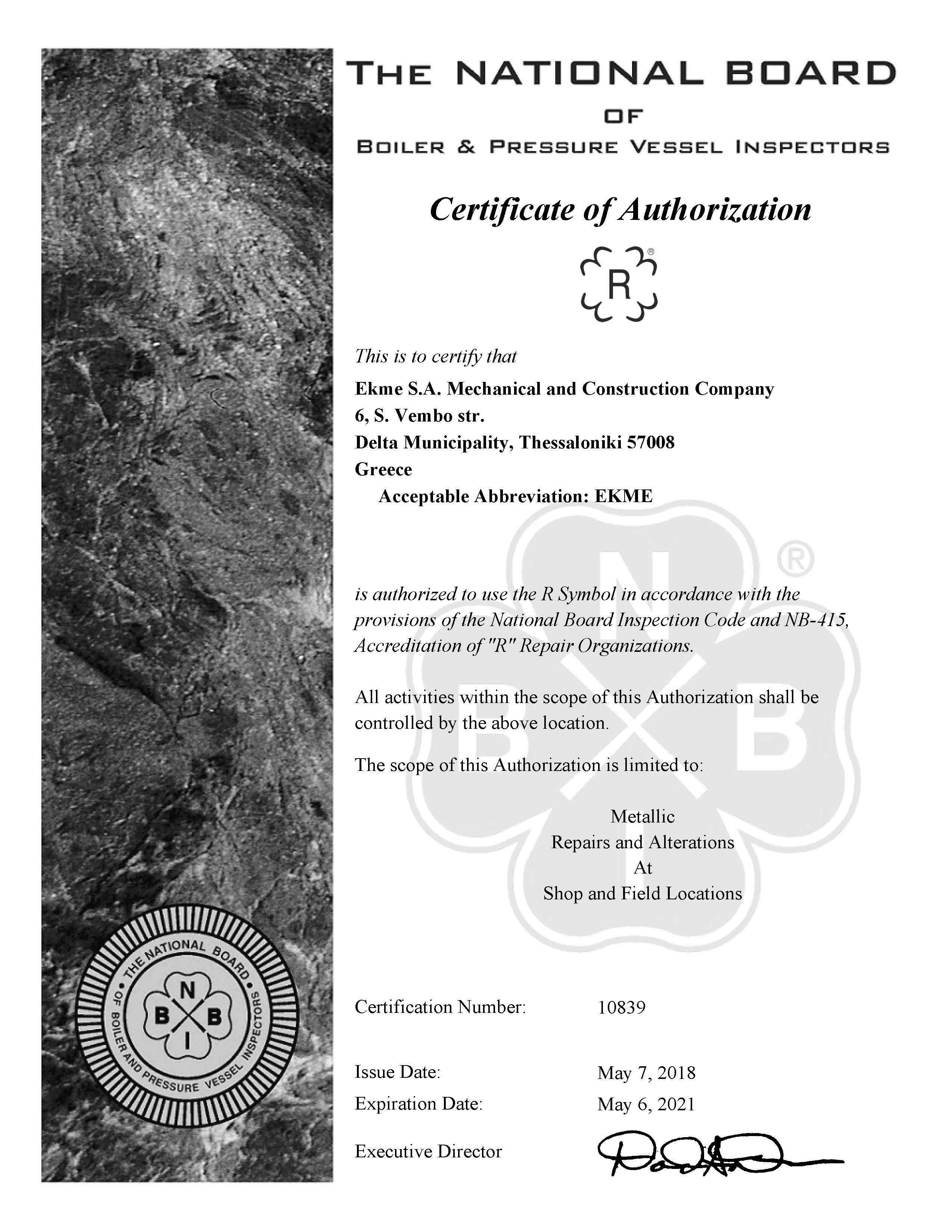

National Board NB, R Stamps

Application of ''NB'' mark and registration of boilers, pressure vessels or other pressure retaining items with National Board.

Use of ''R'' symbol in accordance with National Board and NB-415 Inspection Code provisions and accreditation of ''R'' repair organizations.

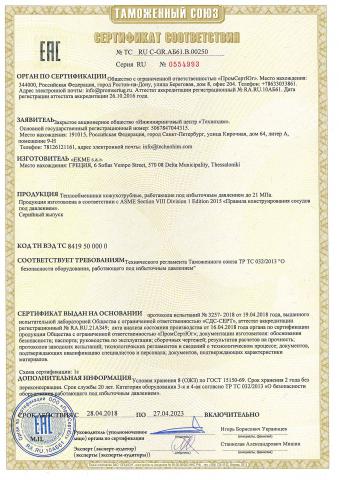

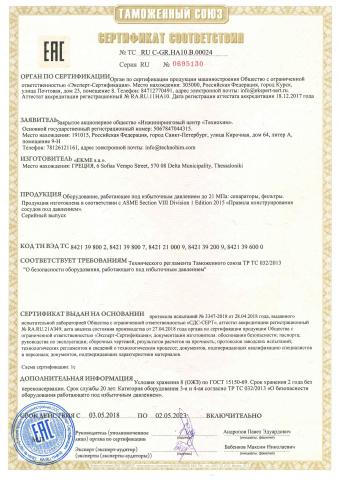

TR-CU-032 Certificates

Product compliance with technical regulations of customs Union of Russia, Belarus, Kazakhstan (Pressure Vessels/Reactors/Columns, Heat Exchangers, Filters/Separators).

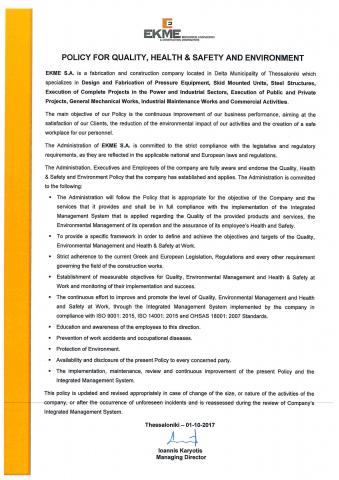

Quality and HSE Policy

Non Destructive Testing Equipment :

| Equipment | Manufacturer | Type / Model |

|---|---|---|

| Hardness Tester | G.E. | MIC-10 |

| UT Thickness Gage | DANATRONICS | EHC-09 |

| UT Conv. & Phased Array | G.E. | PHAZOR XS |

| MT Yoke | MR CHEMIE | MR52 |

| UV Lamp | HELLING | |

| LUX Meter | LX | LX1330B |

| FILM Viewer | KOWOLUX | |

| Densitometer | NDTES | DDS-2 |

| PMI | ELVATECH | PROSPECTOR LE |

| Coating Thickness Meter | KARL DEUTSCH | Pocket - Leptoskop |

| Coating Thickness Meter | ELCOMETER | 456 |

| Ferrite Meter | DIVERSE | MF300F+ |

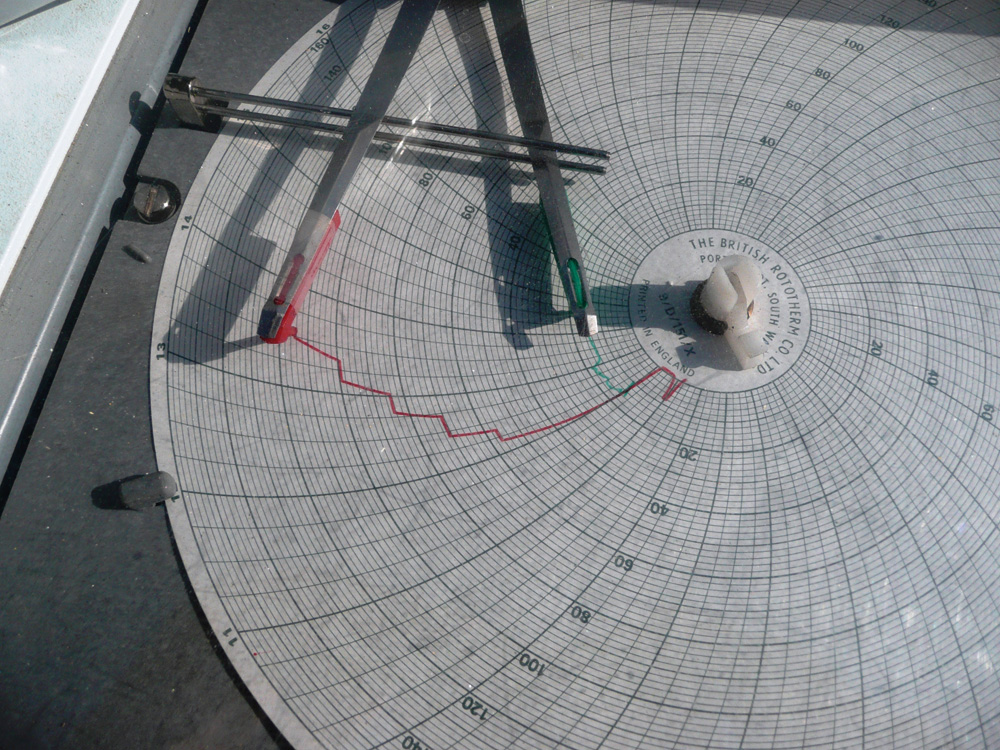

| Pressure / Temperature Recorder |

ROTOTHERM HONEYWELL |

SENTINEL eZtrend GR |

N.D.T. Operators’ Certifications

ASNT and/or EN/PCN Level II certifications of EKME’s personnel.

| ASMT | VT | MT | PT | RT/RI | UT conventional | UT Phased Array |

|---|