In the field of industrial projects, where advanced technical know-how and adherence to strict quality specifications and safety standards are essential, few companies can demonstrate the efficiency, reliability and experience of EKME.

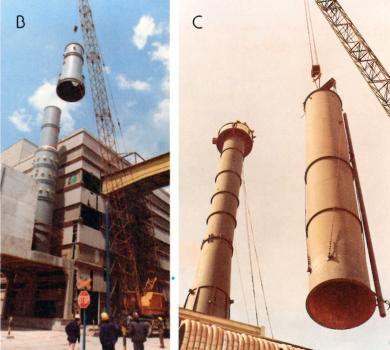

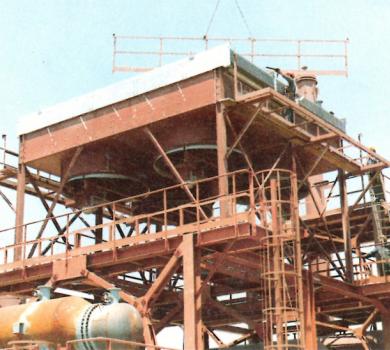

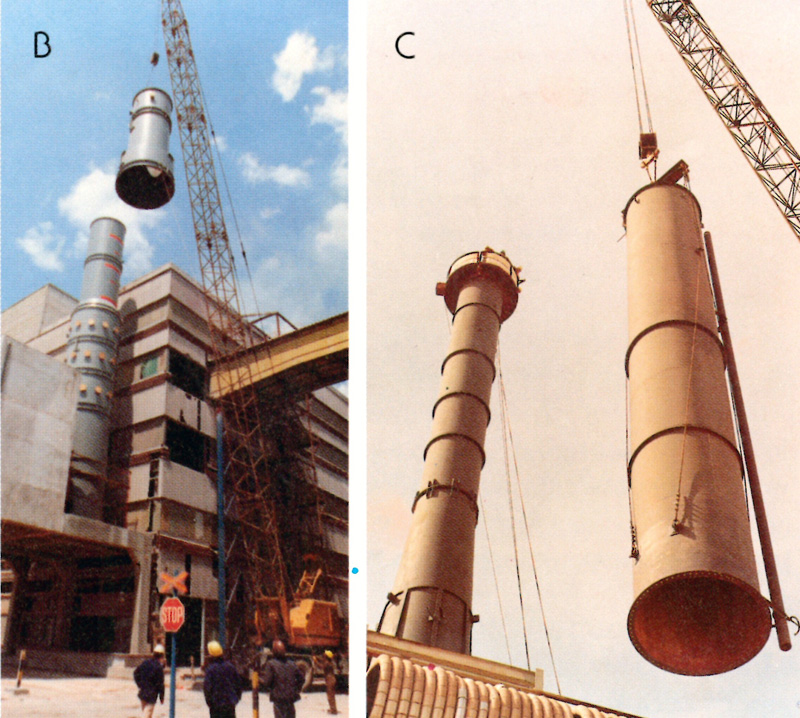

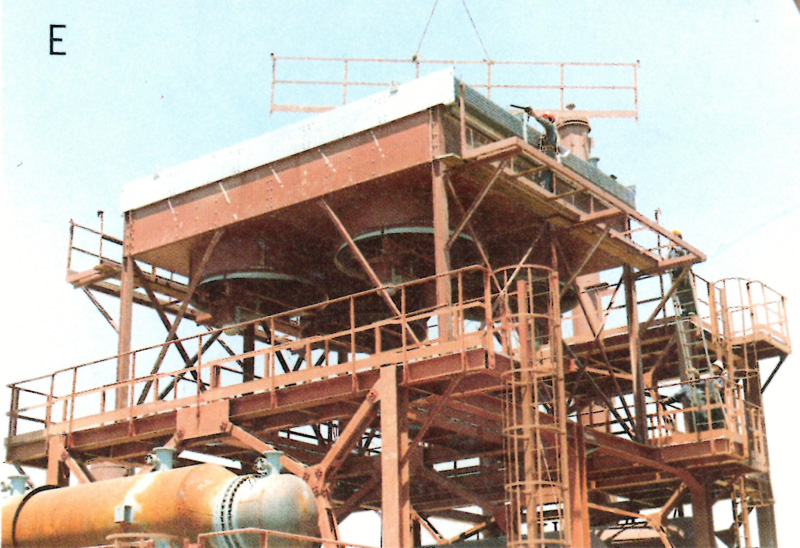

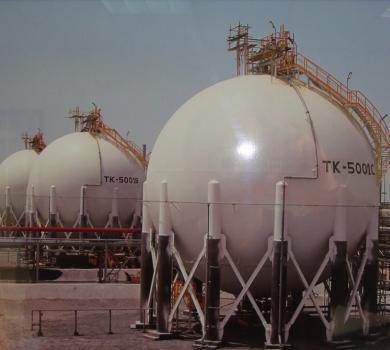

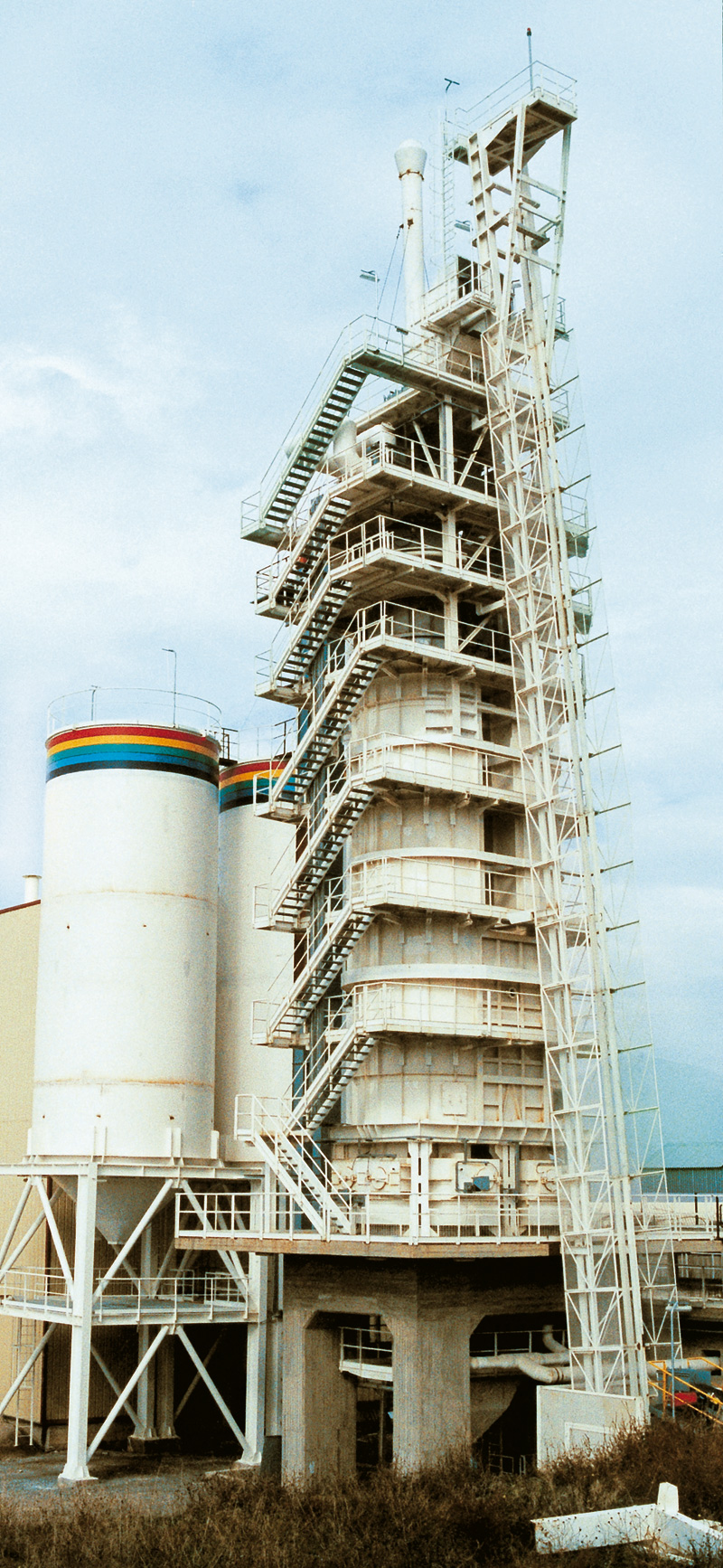

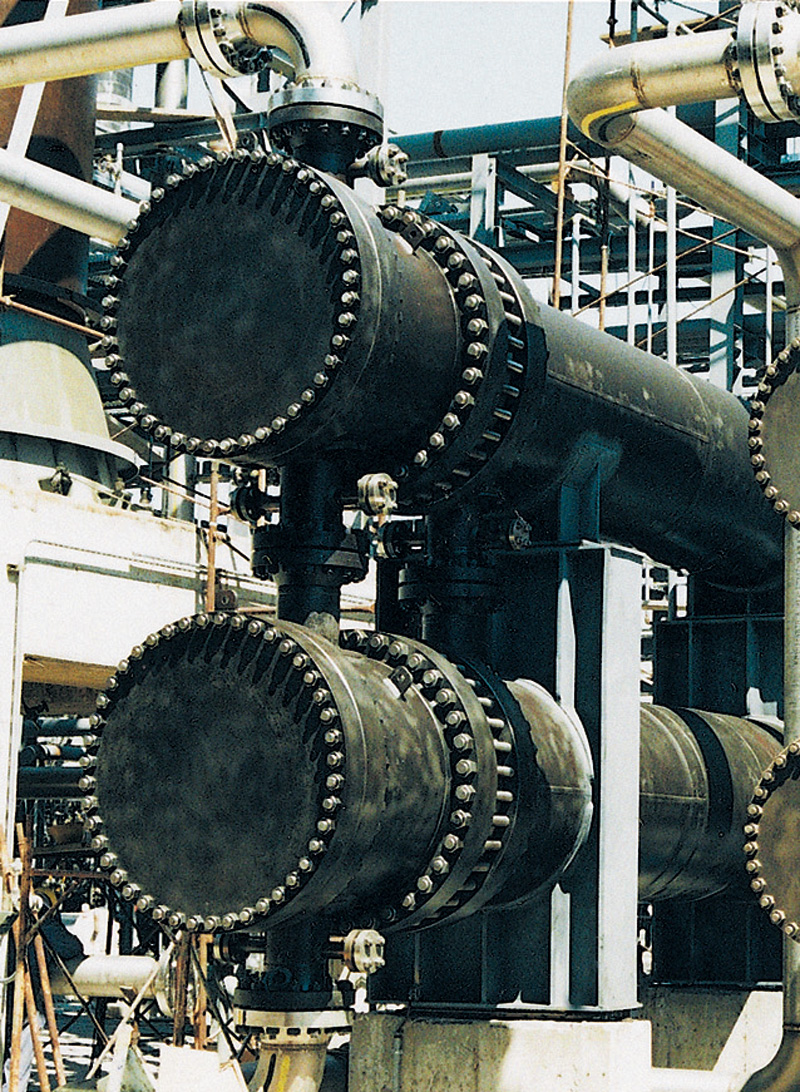

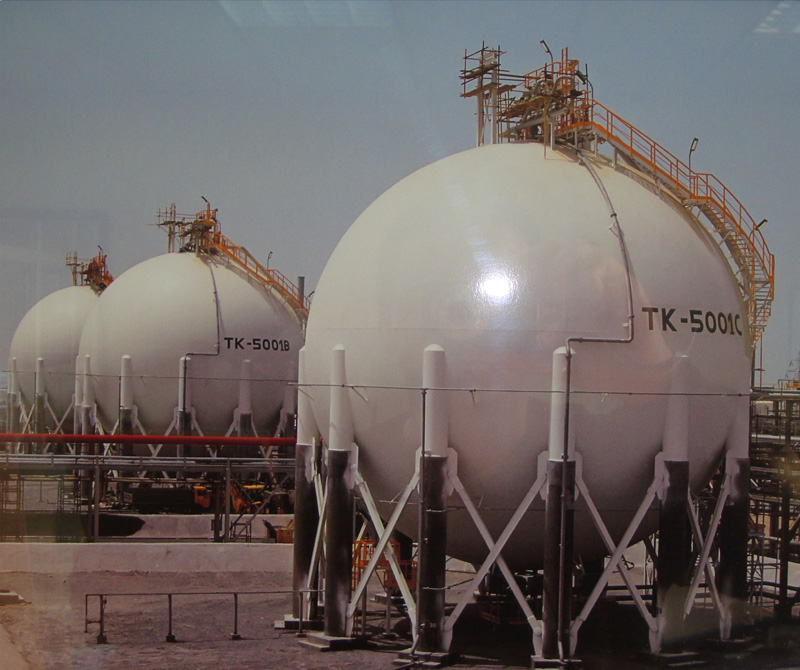

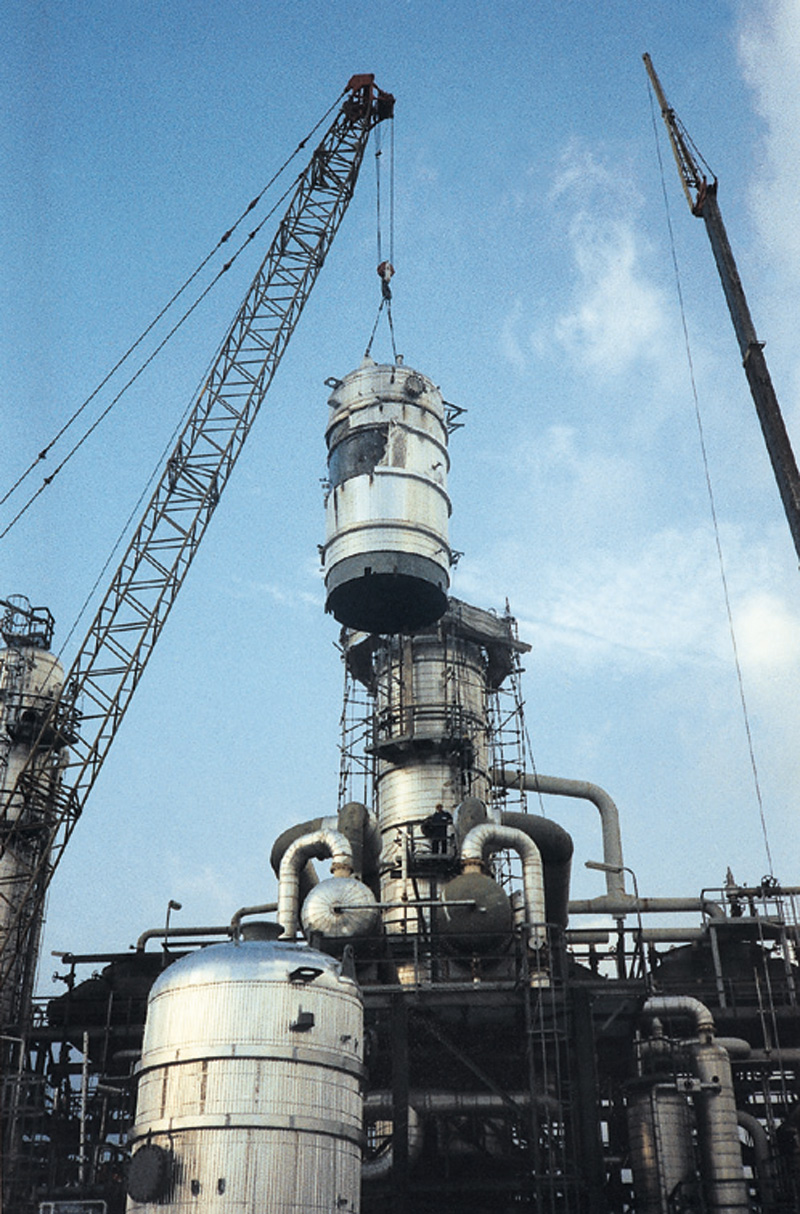

EKME followed the evolution of the Greek industry since the early 70s in the most technologically demanding sectors such as refineries, petrochemical and fertilizer plants, power generation plants, fuel storage and distribution facilities etc.

The company acquired considerable technical knowledge by undertaking the construction and maintenance of industrial plants, where state of the art production applications where introduced for the first time in Greece by internationally reputed engineering firms.

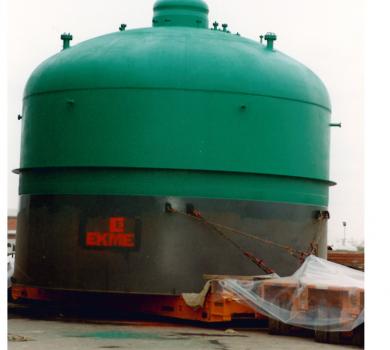

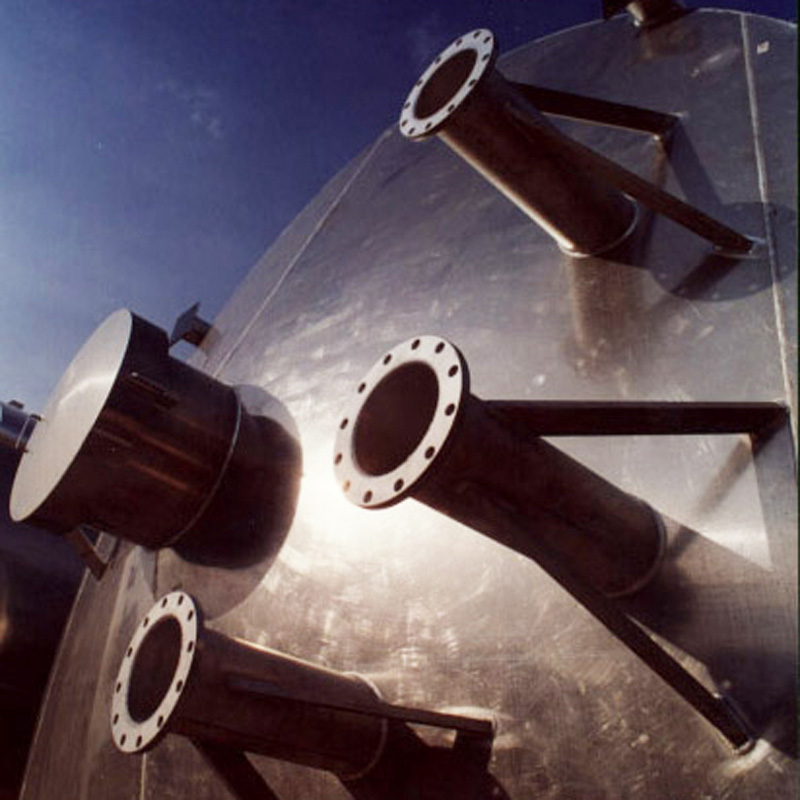

This provided a stepping stone for the company from the early eighties to advance its manpower’s skill level, extend the production capacity of its machinery and structure its organization in a fashion which allows EKME to undertake the execution of complex industrial projects and the fabrication of high specification process equipment.

Through its fourty-year course EKME and its staff, have demonstrated an exemplary ethos, reliability and client oriented culture, all of which have distinguished EKME from its competitors. This distinction is best embodied in the following target statement.

Commitment | Reliability | Excellence